Why Star delta starters are preferred for higher HP motor:

This kind of starter is required to start more than 10 HP motor. Main use of this starter is to reduce the starting current. Due to starting star connection reduces the voltage by 1/ root 3 times. Due to this reduced voltage starting current is limited. This is cheap and maintenance free starter.

What happen when we start the motor through delta connection:

Vph = Vline => Delta connection thumb rule

Vr=Vry

Vb=Vyb

Vy=Vrb

But Line current I line = 1.732 I phase

At that starting time motor speed N= 0, To rotate the rotor from 0 to full rpm it takes 5 to 7 times of its full load current.

Ex: consider 110 KW motor, full load current = 200 Amps, Then the starting current I start = 1000 amps to 1400 amps, due to this change to damage the motor winding

Consider starting star connection:

Vph= Vline/ roor 3

So that applied voltage per phase reduced to 58 %. Due to this reduction, starting current also get reduces. Speed reduces to 70 % of its full load speed. But with star connection we cannot put the load on the motor, because of its reduction in voltage and the starting torque also reduces, to match this, the load current goes higher. That why normally we won’t run a motor with star connection. After 30 sec motor connection automatically changed to delta connection through the contactor logic.

Also see: star delta wiring diagram

Also see: Why induction motor takes larger starting current

To avoid this, we go for star delta starter.

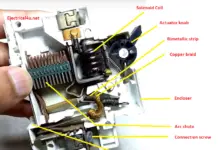

Effect of such DOL starting method:

- Series winding Damage

- MD (maximum demand) will be raised in your energy meter. Unnecessary electricity bill arises.

- Series voltage drop across other parallel feeders. It leads to malfunction in the control circuit.

Advice to provide star/Delta starter:

- Crusher or grinder application where are the place come with heavy starting torque there we must use this starter.

- More than 10 HP

Where we can run with risky DOL starter (more than 10 HP)

- Emergency firefighting pump

- Turbine Jacky pump

- Emergency oil pumps

Better explanation why start delta starter are preferred for higher HP motor:

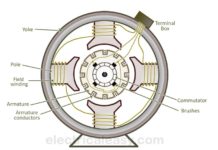

Starting Torque of the induction motor Tst = K E^2 R2/(R2^2 + X2^2)—————–1

Where the motor starts with direct delta connection Here Vline = Vphase

E2 = rotor Emf at stand still

K= constant

R2= rotor winding resistance at stand still

X2= Rotor winding reactance at stand still

Let the motor starting with star connection here Vline = Vphase/root 3

Let sub in 1

Tst at star connection = K ((E2/root 3)^2/(R2^2 + X2^2))———–2

Here Tst at start/ Tst at delta = 1/2 è 1/3 by cancelling each other…

Hence Tst= Tst delta/3

Total delta starting torque reduces by 1/3 times

Torque produced in the induction motor depends on the following Factors:

- The part of the rotating magnetic field

- Rotor current in running condition

- Power factor of the rotor

T directly proportional to flux, rotor current and rotor power factor

By reducing the starting torque of the motor the starting current also reduces, that’s why star delta starters are preferred for higher HP motor

While starting the motor with star connection I st = 3 times of the full load current After 10 secs it comes to 10 % of its full load current. And During delta change over it takes 30 % of its full load current.

![What is Normally Open & What is Normally Closed [Video Included] What is NO and NC](https://www.electrical4u.net/wp-content/uploads/2020/09/What-is-NO-and-NC-218x150.png)