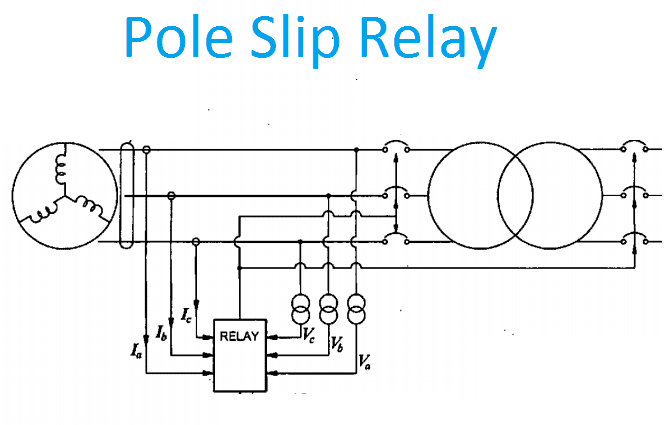

Pole Slip protection or out of step Protection 78PS:

Pole Slip protection: Under normal condition the generator is synchronized with grid. But during some extreme fault condition such as heavy line fault, lightning impulse, switching transient etc. the heavy transient torque may be subjected to the generator winding. Due to that the generator may loss its synchronism and Pole slipping occurs. Pole slipping is nothing but a generator’s rotor produces weak magnetic field or low excitation for the given input or the physical slip occurs in the rotor’s shaft. It can cause severe mechanical stresses within the rotor experiences a sudden physical and electrical shift in position relative to the stator, putting winding at risk, causing shaft damage etc. after which the field recovers enough strength to lock the rotor back in sync with the stator. But the recovery time delay exceeds the safe limit, there is high currents flow in the generator windings which can cause thermal instability and winding stresses, pulsation torques and mechanical resonances that have the potential danger to turbine generator.

[wp_ad_camp_1]

During normal operations of a generator, the output of electric power from the generator produces an electric torque that balances the mechanical torque applied to the generator rotor shaft. The generator rotor therefore runs at a constant speed with this balance of electric and mechanical torques. Under fault condition, the fault reduces the amount of power transmission, the electric torque that counters the mechanical torque is also decreased. If the mechanical power is not reduced during the period of the fault, the generator rotor will accelerate with a net surplus of torque input. This mismatching of torques causes large separation of generator rotor angles, large swings of power flows, large fluctuations of voltages and currents, and eventually lead to a loss of synchronism between groups of generators or between neighboring utility systems

Pole slip is a very serious fault. To minimize the possibility of damage, the generator should trip without time delay approximately during the first half-slip cycle of the loss of synchronism condition.

Working Principle of Pole Slipping relay:

Upon the loss of synchronism, the generator impedance starts increasing while decrease system impedance. The relay set by the generator impedance and the impedance increases the relay starts operating.

Pole slipping relay ANSI Code: 78PS.

Relays acted:

- Flag operation at Protection panel.

b. Acting of Master relay 86M.

c. Indication at Annunciation Panel.

Consequences:

- Tripping of generator breaker

b. Tripping of Field breaker

After Pole Slip Relay Operation:

After the relay resetting, starts rolling the primover, Synchronize the generator with grid.