Stepper Motor

Selection between a servomotor and stepper motor quite will be challenged with balancing of several design factors of the cost consideration, torque, speed, acceleration and drive circuity are the important role in selecting the motor for the application.

What is Stepper Motor:

A step motor or stepping motor is called a stepper motor in which the single rotation is divided into a number of steps. Each step is being calculated by an angle. The step angle can be varied as per the design of the motor.

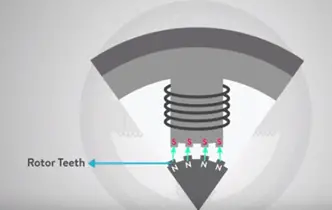

It has a permanent magnetic rotating shaft called the rotor and stationary electromagnets surrounding the rotor called the stator.

Also, It has typically 100 electromagnet poles of north and south poles generated either by a permanent magnet or an electric current.

Each permanent magnetic pole is having a natural stopping point and the position of the poles is placed in the stepper motor position itself accurately and precisely.

This is the convenient features of the stepper motor in that the poles of the stepper motor is allowed to position accurately without any positional feedback.

In other words, it works in an open-loop control system. The open-loop control system opens and allows a single pulse from the controller to move the motor shaft from one pole to the other and stop additional feedback to the controller. This is one of the benefits of the stepper motor.

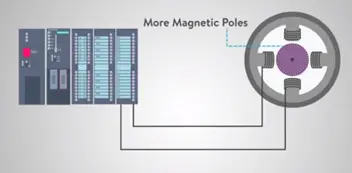

When we want to increase the resolution will achieve the smallest rotation movement designed for a stepper motor contains a large number of magnetic poles.

Basically, the incremental step size of the motor is fixed to the cylinder greaves rotation based on the number of electromagnet poles.

Therefore moving to an accelerate position is simply a matter of sending the commends to the pole of the stepper motor.

Stepper Motor Step Calculation:

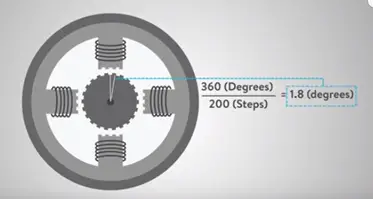

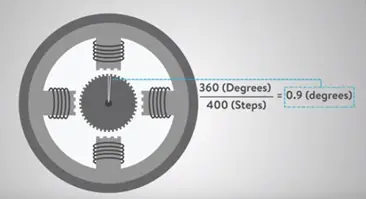

i.e. A Stepper motor has 200 rotor teeth and 200-400 four steps for the revolution of the motor shaft. To determine the resolution of rotation of the motor we can perform a little maths.

If the stepper motor has 200 incremental steps and we know four rotations is equal to a circle where 360 degrees, 360 deg/200 steps = 1.8 degrees. And 360 deg / 400 steps = 0.9 degrees a four-step rotation.

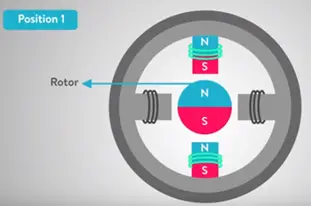

Position 1

The rotor is started at the top of the electromagnet pole which is current energies with the current flowing through a wire. In order to move the stepper motor in clockwise the top of the electromagnet pole will be deactivated.

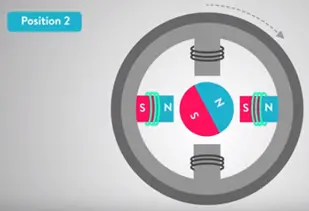

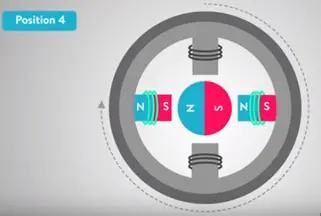

Position 2, 3, and 4:

Now the top of the electromagnet will be deactivated and the right side electromagnet is activated carrying a rotor to move 90 degrees clockwise and align with the active magnet as shown in position 2.

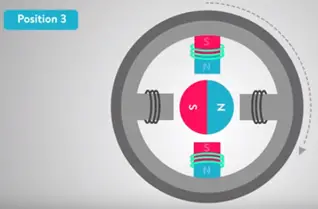

Now it is continued to deactivate and activate the electromagnetic poles around the stator and position 3 and 4 carrying rotor to realign with each new electromagnet pole to enable to rotate the rotor 90 degrees in clockwise in each time.

This eventually completes a 4th 360 degree of rotation. Hence, remembering the basic properties of like magnetic pole repels and low and unlike poles attract depending on the power source current is applied to an electromagnetic pole coil wire.

It causes like and unlike magnetic attraction and retraction forces in the permanent magnet to rotate the motor.

In the real word, the stepper motor incorporates a large number of electromagnet poles on the stator and rotor to increase the resolution.

With the increase in the number of electromagnet poles, the operation is basically the same as the example providing 90-degree rotation.

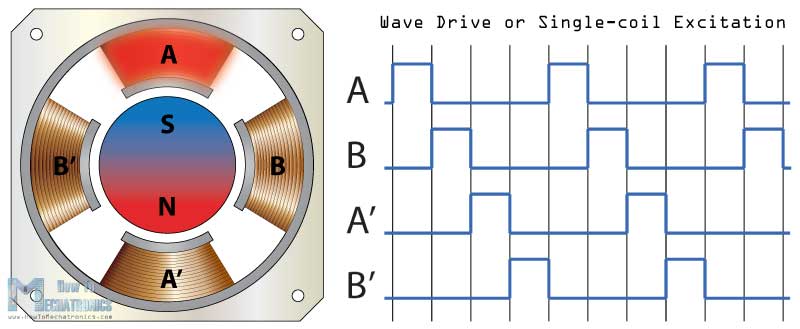

The pules are given as below,

Multiple steppers motor:

Refer to the below mentioned animated working principle of stepper motor with multi-step action.

Frame 1: The rotor is designed in the upper position 1 with top stator electromagnet -1 will be activated. It attracts the nearest geared pole in the rotor. Then the rotor starts rotating. They will be slightly offset from the right electromagnet

Frame 2: The top electromagnet 1 is deactivated, and the right side electromagnet 2 will be activated, pulling the teeth into alignment with it. i.e consider we have 100 steps motor. It gives 3.6 deg (360/100=3.6) of rotation for each steps.

Frame 3: The bottom coil 3 is energized (1 and 2 will be deactivated); hence another 3.6° rotation occurs.

Frame 4: The left electromagnet 4 in the stator is energized (1,2 and 3 will be deactivated), hence we get another 3.6° rotation.

Again the top coil of stator 1 will be enabled, then the same process continues. By energizing and de-energizing of the stator’s electromagnet, we get 360° rotation.

By fastening the electromagnetic polarization we can increase the speed of the motor.

Image Credit:

![What is Arc Chute? Types, Working Principle [Video Included] arc chute working priciple](https://www.electrical4u.net/wp-content/uploads/2020/06/arc-chute-218x150.png)