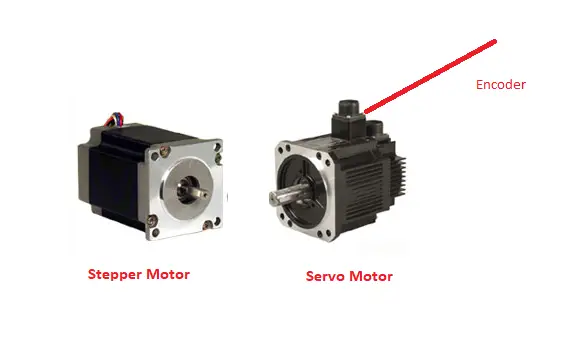

Difference Between Stepper Motor and Servo Motor:

Servo motor and stepper motor both are DC motor and they are commonly used in the robotics, industrial automation, PLC controllers etc. but selection of motor will be based on the application. In this article we are going to discuss about the difference Between Stepper Motor and Servo Motor.

-

Definition:

We can understand the name itself, servo means continues function but stepper means step function, from that servo motor runs continuously based on the command, but Stepper motor rotor moves based on an angular location.

2. Pole:

Stepper motor is designed with multiple numbers of poles to get desired steps, typically 50 to 200 numbers of poles. Hence it moves accurately between the poles, whereas Servo motors are designed with 2 to 12 number of poles. Hence, to reach desired output servo motors to be rotated higher RPM typically above 2000 RPM.

3. Encoder:

Encoder is a device which is used to convert physical action into electrical signal to give closed loop feedback. In servo controlled system, the encoder is a mandatory device to track the accuracy of their position. But stepper motor doesn’t require such encoders since they can accurately move between their poles.

Steppers simply move discrete steps using single pulses like open loop system. But servo’s controller reads the error signal between command position and actual position like closed loop system. According to this error signal, the controller decides the input of the servo motor.

Encoding system is the major difference between stepper motor and servo motor.

4. Torque:

As the basic operation of the dc motor, while increasing the torque of the motor, the speed of the motor will be reduced. In such way that, stepper motor moves the rotor at very lowest RPM, from 0 to 1 RPM. Due to slow movement of the rotor, the torque experienced in the winding is high. Hence to complete one rotation, the stepper motor is required much current than servo motor. Stepper control systems are less expensive in low-to-medium acceleration, they have high holding torque; they can adopt both open or closed loop operation.

Servo motor moves high RPM, hence the torque experienced in the coil is less with respect to speed as compared with stepper motor, this is the fundamental data is used to design the driver circuit of both motors. Servo control systems are best suited to high speed, high torque applications that involve dynamic load changes.

5. Cost:

Steppers are simpler to commission and maintain than servos. They are less expensive, especially in small motor applications. It does not require encoder or controller to read error signal. Servo motors are costlier since they are incorporated with encoders.

6. Application:

Stepper motor is suitable for low and medium acceleration application; they hold their position without any fluctuation, especially with dynamic loads.

Servo motor is suitable for higher acceleration application example motorized valves.

Great article. Thanks for sharing the useful information. It’s important to know the difference between a servo motor and a stepper motor. It will save them save a lot of time in selecting between the motors.