Switched Reluctance Motor (SRM)

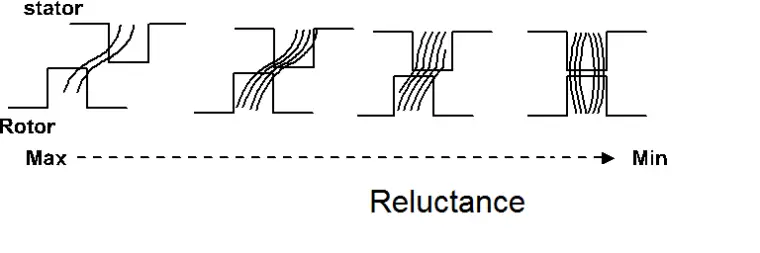

Switched reluctance motor works based on the variable reluctance principle. The rotating magnetic field is created with the help of power electronics switching circuit.

The main concept is the reluctance of the magnetic circuit is depending upon the air gap. Hence, by changing the air gap between the rotor and stator, we can change the reluctance of the motor.

Note: reluctance is nothing but a resistance to the magnetic flux. (Opposes the magnetic flux. For Electrical circuit it is resistance and magnetic circuit it is reluctance).

Construction of SRM

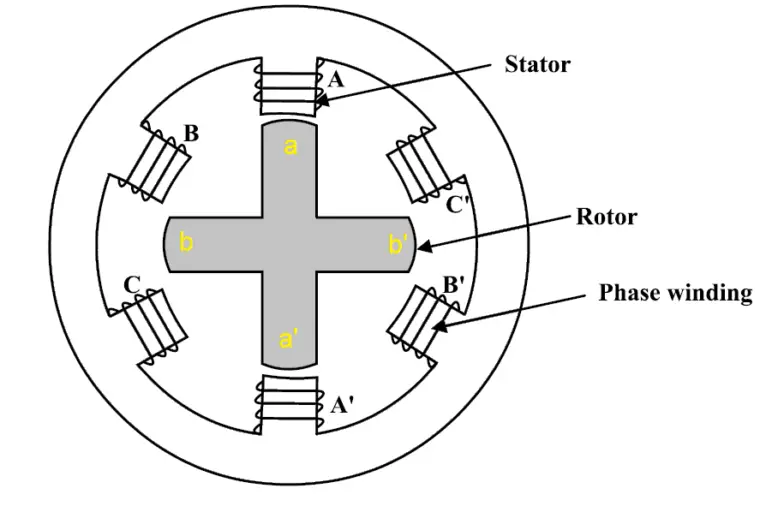

In switched reluctance motor, the stator and rotor have projected pole made up of soft iron and silicon stampings. Silicon stamping is used to reduce hysteresis losses.

Stator => Inward projection

Rotor => Outward projection.

The rotor does not have winding and stator only carries main field winding. Each winding in the stator is connected in series with the opposite poles to increase the MMF of the circuit. It is called phase winding. Refer to fig 1.1 AA’, BB’ and CC’.

Pole concern, the number of poles in the stator will be around 6 to 8 numbers. But the rotor carries less number of poles with respect to the stator. The rotor poles will be 4 to 8 numbers.

By increasing the number of poles we can get a low angle of rotation from the motor. The rotor’s shaft is mounted with a position sensor. The position sensor is used to determine the position of the rotor by a control circuit.

The control circuit always collects the information of the rotor position and based on that the controller gives the input to the motor.

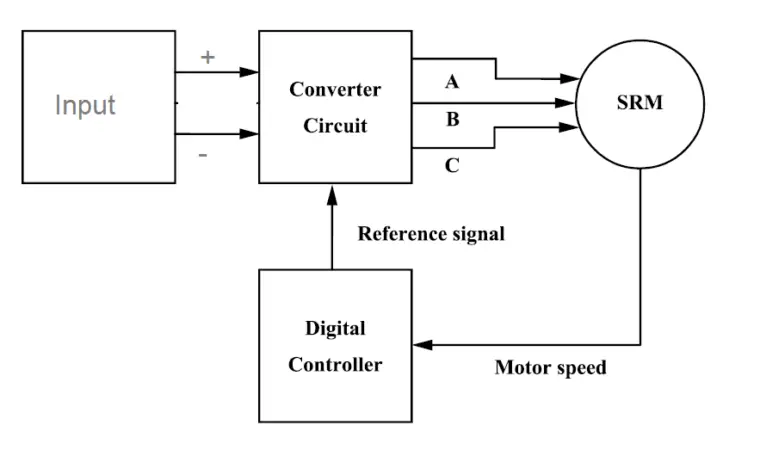

Block diagram of SRM

The DC input is connected to the driver/converter circuit and the output is connected to the motor. The rotor sensor’s feedback wire is connected to the controller circuit and it provides the position of the rotor with reference to the reference axis.

Finally, the controller collects all information and based on that, reference will be given to the stator. Also, the controller monitors the motor current to protect the motor from internal and external faults.

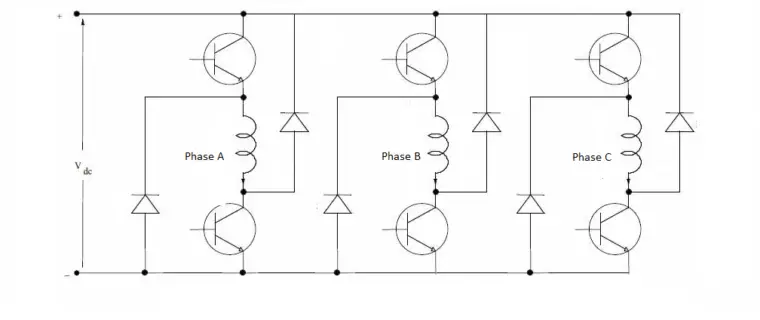

The converter circuit:

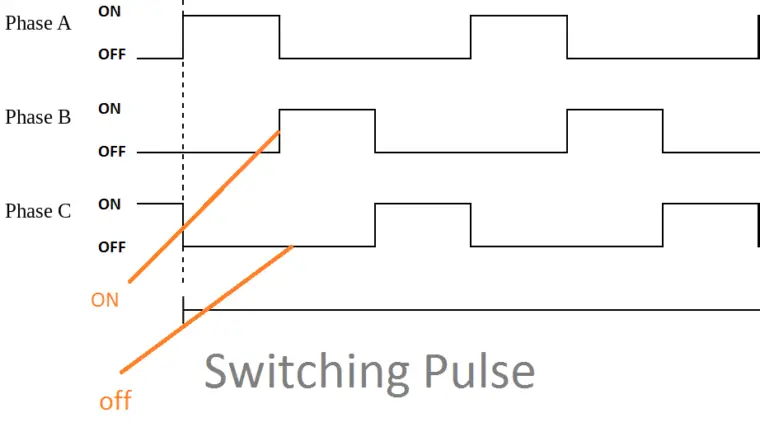

Also, note that the output of the controller is DC. And the output will be as shown in the figure 1.3.

Working Principle

The working principle of switched reluctance motor is simple, let we take an iron piece. If we keep it in a magnetic field means, the iron piece will align with the minimum reluctance position and get locked magnetically.

The same principle is followed in the switched reluctance motor. The minimum reluctance portion of the rotor tries to align itself with the stator magnetic field. Hence the reluctance torque is developed in the rotor.

In our motor, let us consider the following notation for better understanding.

Stator Poles:

AA’ poles axis for A phase

BB’ poles axis for B phase

CC’ poles axis for C Phase

Rotor poles:

aa’ rotor poles axis for Position 1

bb’ rotor poles axis for position 2

Now the input is given to the A-phase, other B and C phase neither maximum nor minimum, then stator pole axis AA‘ and rotor pole axis aa‘ are in alignment. Ref picture Fig 1.4

Figure 1.4 indicates that the A-phase reached the minimum reluctance position.

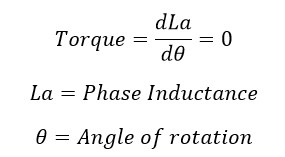

Because the air gap between the stator and rotor is very less, and they are minimum reluctance position as compared with other poles. Then,

Now, Phase A will be turned off and the B phase is energized. Then the rotor axis bb’ turns to stator axis BB’. Move clockwise as per our diagram. By changing the polarity of the motor, we can easily reverse the motor.

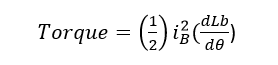

The torque develops since the reluctance changes from maximum to a minimum. The developed torque is equal to

The rotor movement is depending upon the number of poles and in our case, we get 30 deg rotation by energizing one phase at a time.

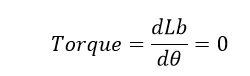

Guys here torque is nothing but a rotor movement only. When the shaft reaches to position BB’. Then there is no torque.

Now the B phase will be turned off, and the C phase will be turned on. Then the torque is developed because of rotor axis aa’ is aligned with the stator axis CC’. The rotor continues to rotate for another 30deg.

Again C will be turned off and A will be stared. The motor operation continues until the input power supply. Here you can observe that the motor is rotating by self. Thus Switched reluctance motors are self-starting motor.

The control circuit continuously monitors the motor speed and input current. if the motor speed falls with respect to the reference, then the control considers as there is a requirement of high torque.

Therefore, it increases the input current to the motor to meet the speed requirement. In case if the motor current is reached beyond the full load current, it trips the motor.

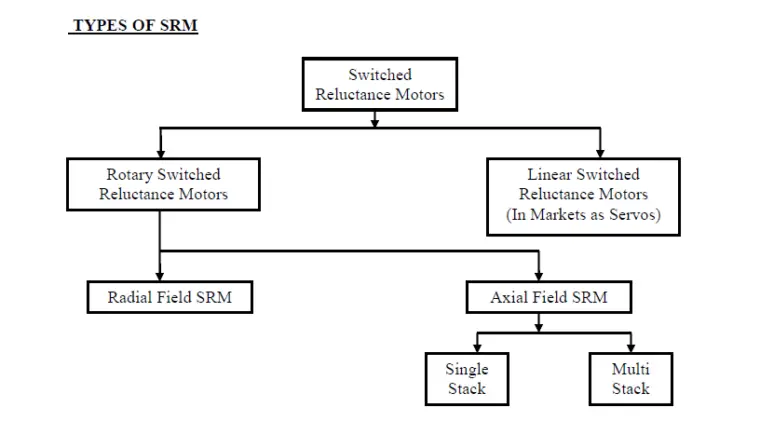

Types of Switched Reluctance Motor

Based on the construction the SRM is divided into two categories. One is linear SRM and another one is rotary SRM.

Linear SRM: Single-step Stator and rotor

Rotary SRM: More than one step stator and rotor

Advantage of SRM

- It does not require an external ventilation system as the stator and rotor slots projected. The airflow maintained between the slots.

- The rotor does not have winding since therefore no need keeps the carbon brush and slip ring assembly.

- Since the absence of permanent magnet, such motors are available at a cheaper price.

- Simple three or two-phase pulse generator is enough to drive the motor

- The direction of the motor can be reversed by changing the phase sequence.

- Self-starting and does not require external arrangements.

- Starting torque can be very high without excessive inrush currents.

- High Fault Tolerance

- Phase losses do not affect motor operations.

- High torque/inertia ratio

- High starting torque can be achieved.

The disadvantage of Switched reluctance motor

- Creates Torque ripple at high-speed operation

- The external rotor position sensor is required.

- Noise level is high

- At a higher speed, the motor generates harmonics, to reduce this, we need to install larger size capacitors.

- Since the absence of Permanent Magnet, the motor has to designed to carry high input current. It increases the converter KVA requirement.

Application of SRM

Domestic appliances such as washing machines, vacuum cleaners, fans etc.